CD Printing – using a white base

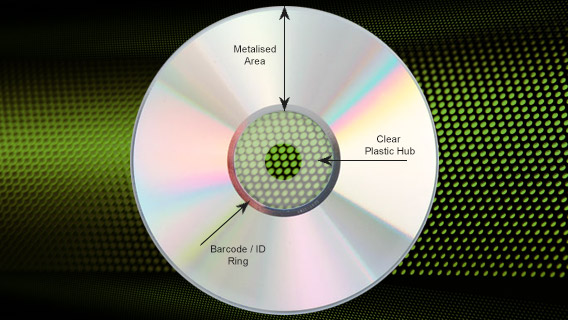

A CD disc has 3 different areas and the surface of each area is different. There is the main playing area, made from polycarbonate plastic which is coated in silver on the non-playing side, an ID ring – which is a shiny metallic silver colour printed onto the inner plastic ring – and a clear plastic hub. The recordable surface and ID ring are not constant silvers, and if you are not using a white base then the different areas can significantly affect any finished design.

A white base is used to provide a neutral base layer and covers the ID ring and inner plastic hub. It basically acts like white paper, providing an even surface for more accurate colour printing. When printing CMYK onto CDs we would recommend that you specify a white base as printing CMYK onto a disc without a white base results in a washed out finish.

If you would like your disc design to include some ‘silver disc shine through’ either the basic silver shine through or some part of the design/colours printed direct onto the silver disc then we would suggest you use a custom white base. You will need to supply 2 different artwork files – one with your full design which will be printed onto a white base, and another showing just the area you would like knocked out. Remember, if you are undertaking this then it is important that the 2 separate artwork files are accurate, if there are any spaces or overlaps between the white base design and the second knocked out design then the end result will mean that the finished disc design will have outlines or halos, the colours will be different if any overlap is present and the design will not look sharp – so it can be a bit tricky.

We would generally recommend using a white base for disc printing. Give us a call if you need any more information – we’re always happy to help.